Wool Grading – End of an Era

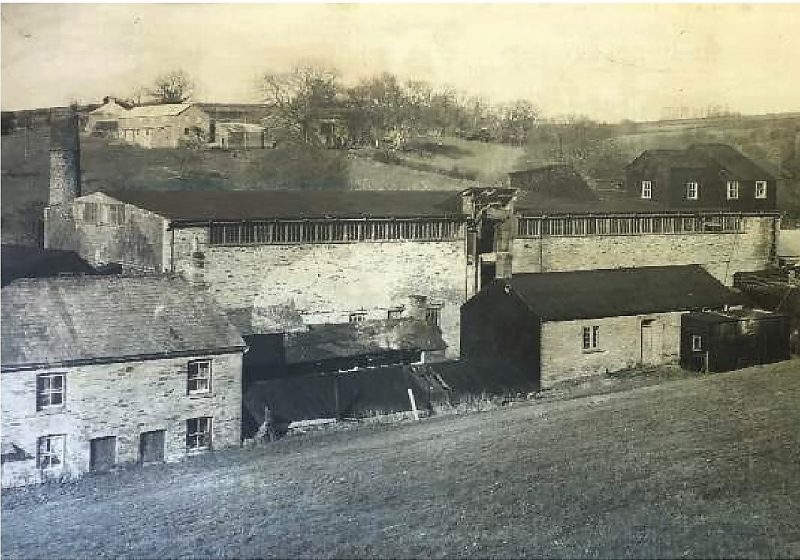

Milestone in town’s long association with The wool depot at Lamellion, Liskeard.

We’re taking a look back at the town’s close association with the wool trade — a history that may well stretch back more than 2,000 years. Evidence of the hand tools used in the earliest wool processing has been found at Iron Age sites in Cornwall. As the site of an Iron Age settlement, Liskeard Hillfort School may once have been the place where the combing of sheep and teasing of fleece into yarn took place, as well as the bartering of wool for other goods.

Liskeard’s early growth from its first mention in the Domesday Book was fostered by its wool market. In his History of Liskeard, John Allen writes that in the 17th and 18th centuries, the yarn market in the town was considerable. By the mid-18th century, two thirds of the labour market were employed in some way connected with wool, and Daniel Defoe, on his 1726 tour of Cornwall, spoke of Liskeard being “remarkable for its manufacturies, with spinners encouraged by the woollen manufacturers of Devonshire”. He described long trains of packhorses to be seen carrying the wool and yarn.

The gradual industrialization of wool production hit Liskeard hard, and its cottage industry was in decline in the late 18th century. The introduction of the Spinning Jenny led to two thirds of British textile exports coming from the northern mills.

Hundreds of appointments rescheduled due to junior doctor strike at Royal Cornwall Hospitals The loss of work that could be done at home for a moderate wage was severely felt in Liskeard and surrounding villages.

While many spinners had to turn their hand to other work, the role of Liskeard and its surrounding agricultural land in the production of wool continued. A revolution for farmers came with the invention of the Wolseley sheep shearing machine in 1877.

The wool factory at Lamellion was established by John H Blamey in 1883 to complement the successful agricultural merchants Blamey and Morcom. John’s son Cubitt joined the operation shortly after his return from war in 1918 and took over on his father’s death in 1923. The factory was later sold to Devon and Cornwall Wools, who were contractors for the British Wool Marketing Board — today, British Wool.

Paul Day, who was employed at Lamellion from 1966 to 1990, describes how the fleeces were first broken into small pieces, then washed in hot water and industrial soap, before being dried and coming out white as snow.

The wool was weighed, graded and baled up into 8,000 kilo lots ready for auction and delivery out to buyers, mostly the wool mills of Yorkshire.

The practice of washing the wool changed in 1969 following concerns about pollution in the East Looe River. A three-storey building at Lamellion then became redundant and was to be demolished: contractors removed the roof and three of the walls, intending to finish off the next day. Overnight, the remaining wall collapsed onto the canteen where Paul Day and his colleagues had been eating their crib just hours before. Thankfully the building was unoccupied — the demolition team returned to clear the rubble away off the Looe Valley Railway line.

Up until most recently, the depot at Lamellion has continued to process around one million tons of wool each year, taken from some 1,500 producers across Devon and Cornwall.

And the thread of the town’s long wool heritage has been taken up by the committed group of crafters, 3 Bags Full, who founded a popular and successful wool market in the Public Hall.

But for farmers continuing to produce fleece for auction, and for the industry in this country, the coronavirus pandemic has brought huge challenges to an already difficult outlook.

The depletion of British Wool’s customer base in the carpet market due to the closure of hospitality venues has combined with a global over-supply of cross-bread wool, leading to prices plummeting.

In dire straits, some farmers have turned to using wool for compost or even to burning fleeces.

British Wool says it has to respond to these changing circumstances and it will be closing four of its eight grading depots. It says this will mean a saving of £1.5million a year, which it can pass on in the form of savings per kilo of wool to its farmers, who own the organisation.

British Wool says its determined to come through and that it will work hard to support the recovery of the wool trade post COVID-19. The depot at Lamellion will continue to take wool until mid-February, and producers will be contacted ahead of next season to let them know where a new intermediate (collection) depot will be located.

With thanks to Brian Oldham, whose virtual talk on The Wool Trade in Liskeard was part of Liskeard Unlocked 2020.